Conveyors for containers

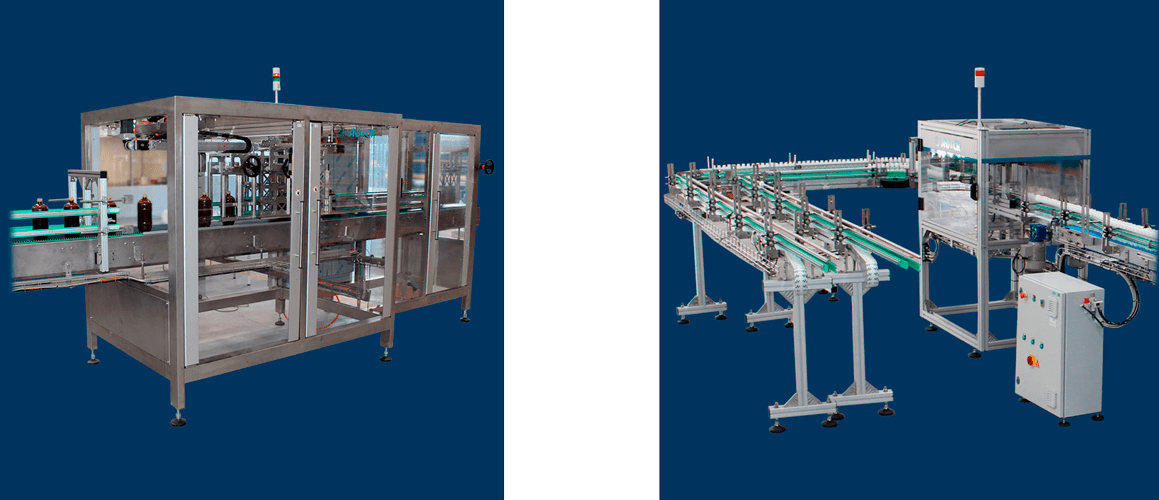

Conveyors for containers, bottles and packs

Container conveyors are mechanical systems used to move containers from one location to another within a factory, warehouse, or production line. These conveyors can be of different types, such as rollers, bands, chains, among others, and can be used to move containers of different sizes, weights, and shapes. Container conveyors are used to improve efficiency and reduce the physical effort required to move containers manually.

Types of Conveyors

For the transport of containers, both full and empty, we have all kinds of systems:

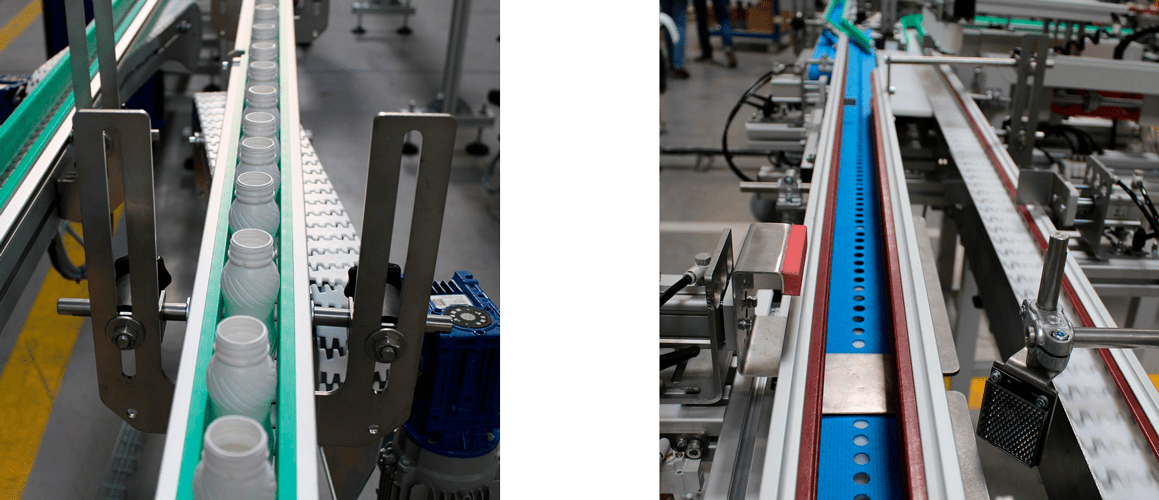

Belt conveyors for bottles

Straight belt conveyors, with possibility to add vacuum element for a better empty plastic bottle stability, and for high-speed production rates.

Chain conveyors with stainless steel chassis

Built in stainless steel, they include a flexing chain so that curves can be used in a single motorized section.

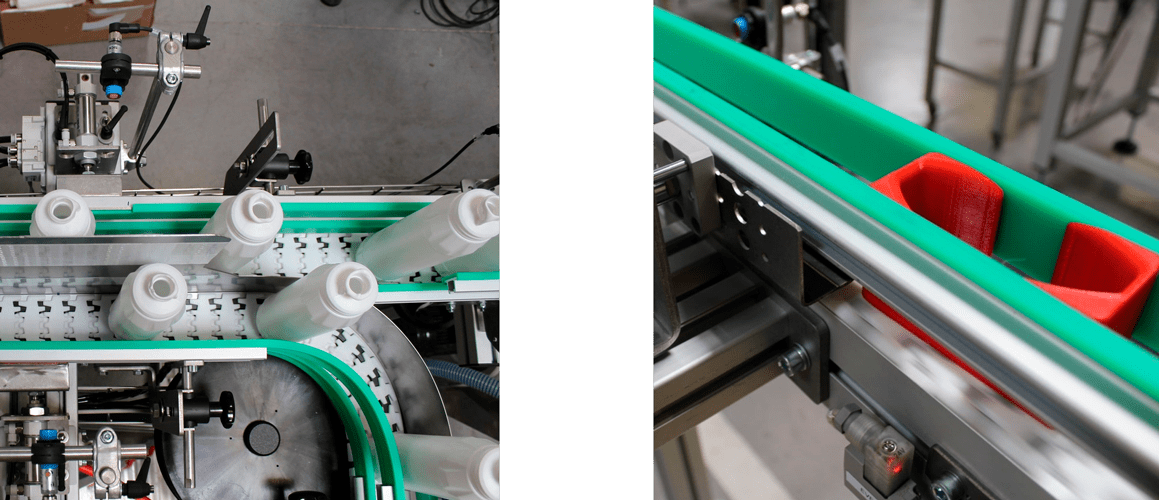

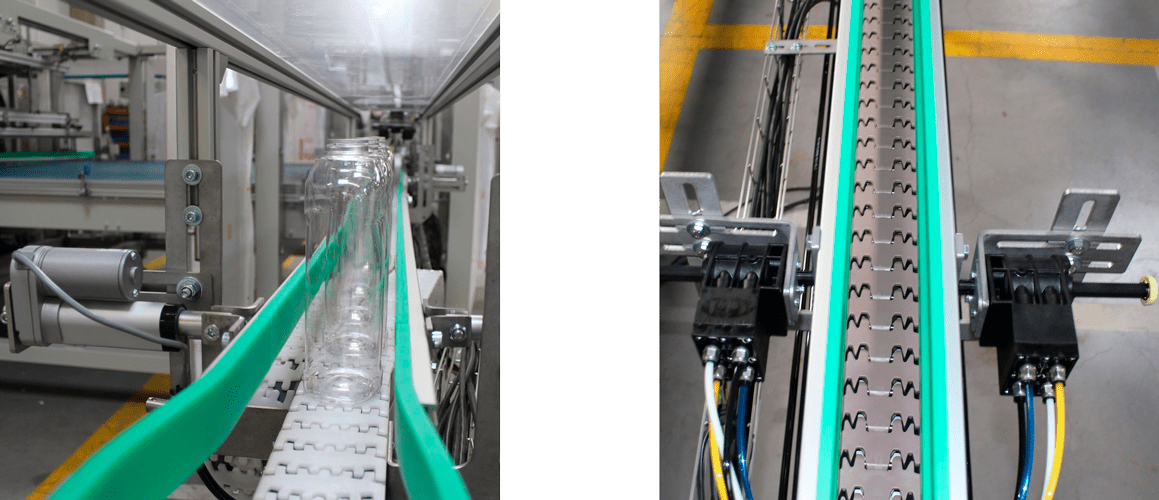

Modular chain conveyors with aluminium chassis

Built with an aluminium conveyor beam and a nylon chain. Sharp curves with range under 150 mm allowing accumulation bottles in small spaces. The greatest advantage of this type of conveyor is that it is maintenance-free. They are installed in dry area.

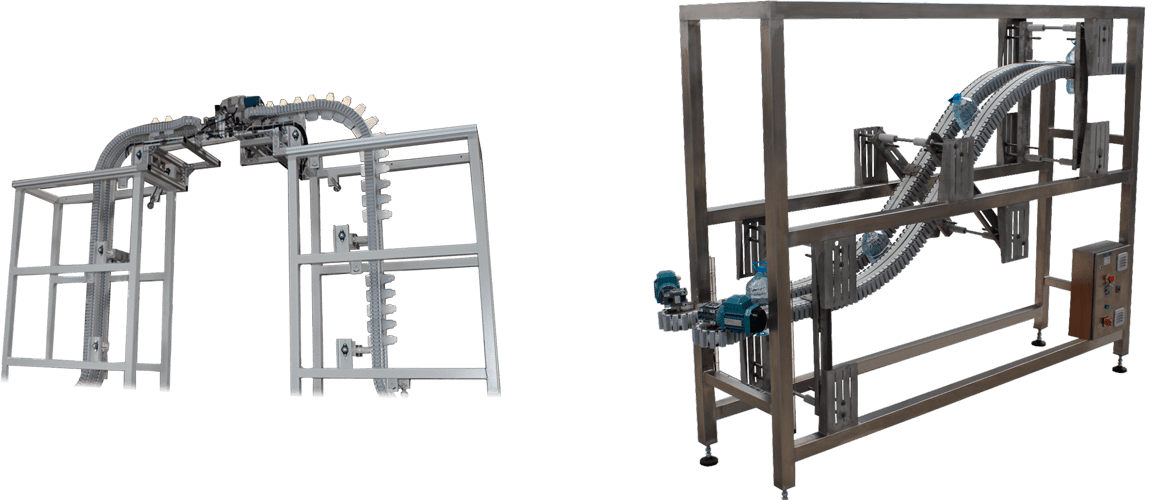

Bottles

elevator:

Bottles elevation and descent conveyors, with flexible chain. Allows a better access in plant taking the transport at height. Elevation up to 7 m height.

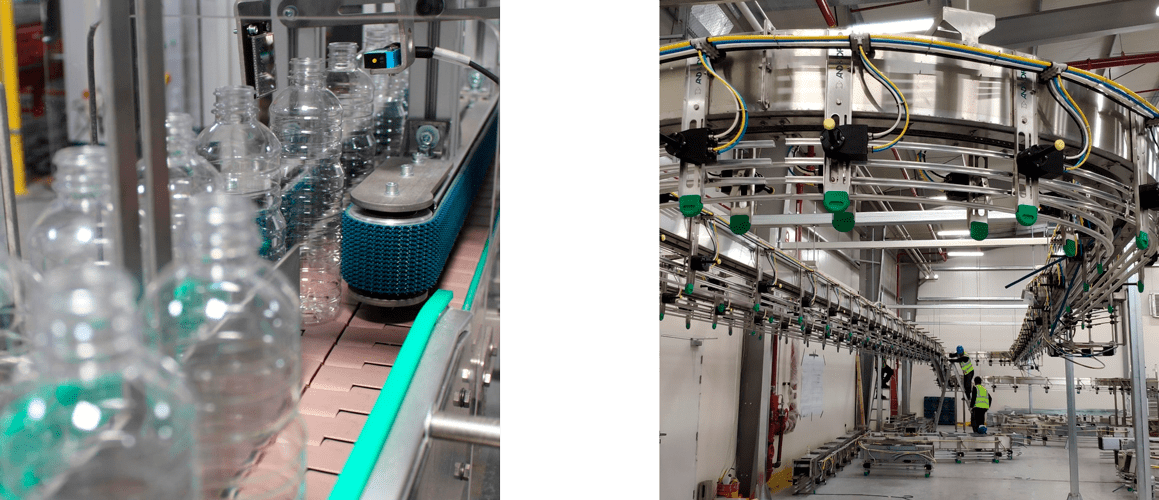

Air conveyors:

Pneumatic conveyors built in stainless steel. Guides regulation can be manual or automatic. They are recommended when working at medium/high production rates for empty bottle (light or unstable transport), from the blower to the filler.

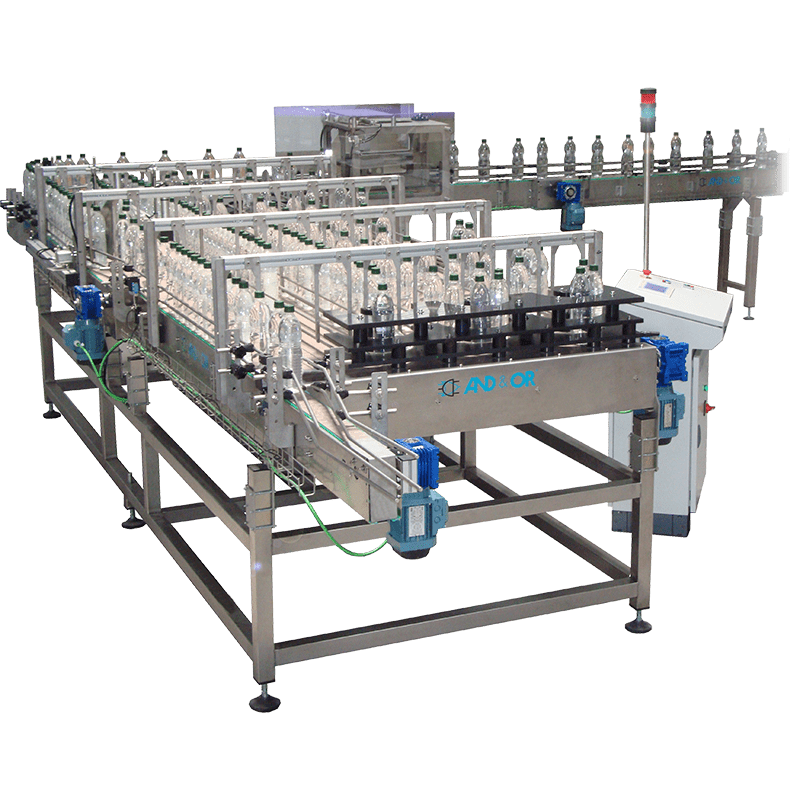

Unifying and dividing systems:

Allowing to go from multi-lane to single lane conveyor and vice versa.

Turning/positioning devices:

For the turning and positioning of the bottles, AND&OR offers diverse systems depending on bottles’ shape, line speed, turning degree (45º, 90º, 180º, etc.). Our models can be pneumatic, motorized and servo motorized.

Automatic regulation guides:

Allowing fast and accurate format changeover in a totally automatic way.

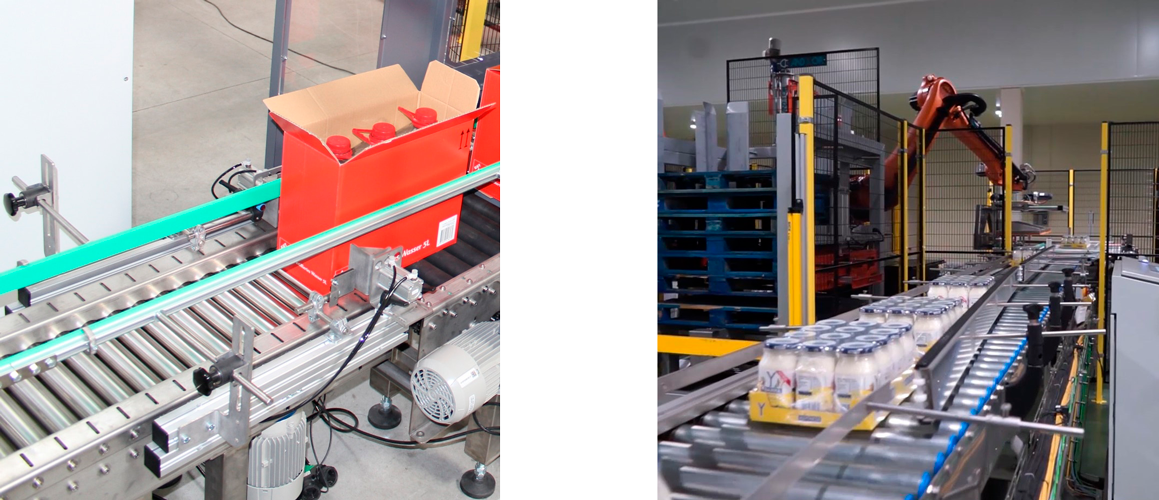

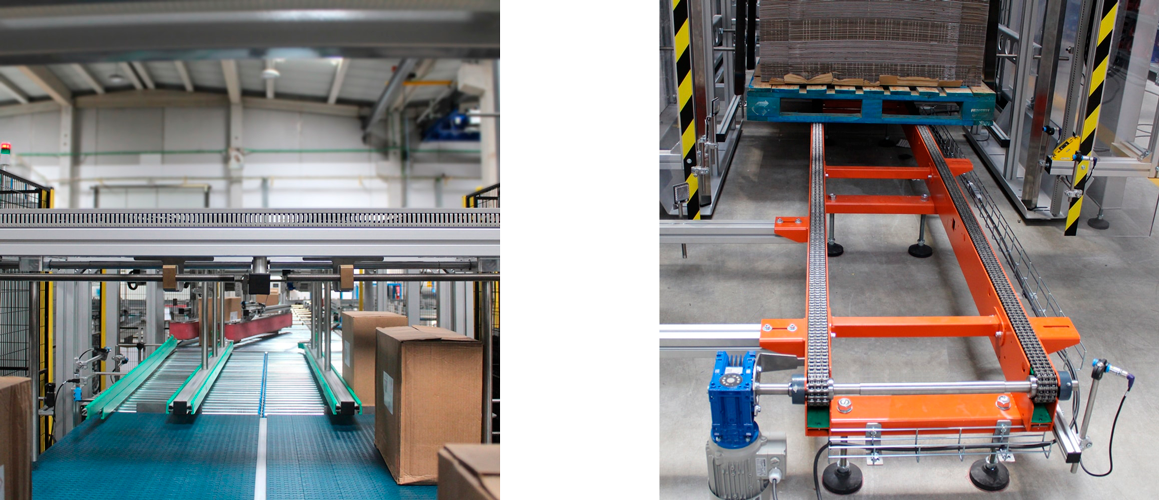

Box and/or pack conveyors:

Secondary packaging conveyors, designed for conveying and handling of carton box, trays, shrink wrap packs, or shrink wrap packs with tray combination. They could be rollers made up with traction roller modules, gummed rollers or friction rollers depending on the line configuration or flap top modular wire mesh, perforated modular wire mesh, gummed modular wire mesh or modular wire mesh with low friction with idler roller according to layout configuration.

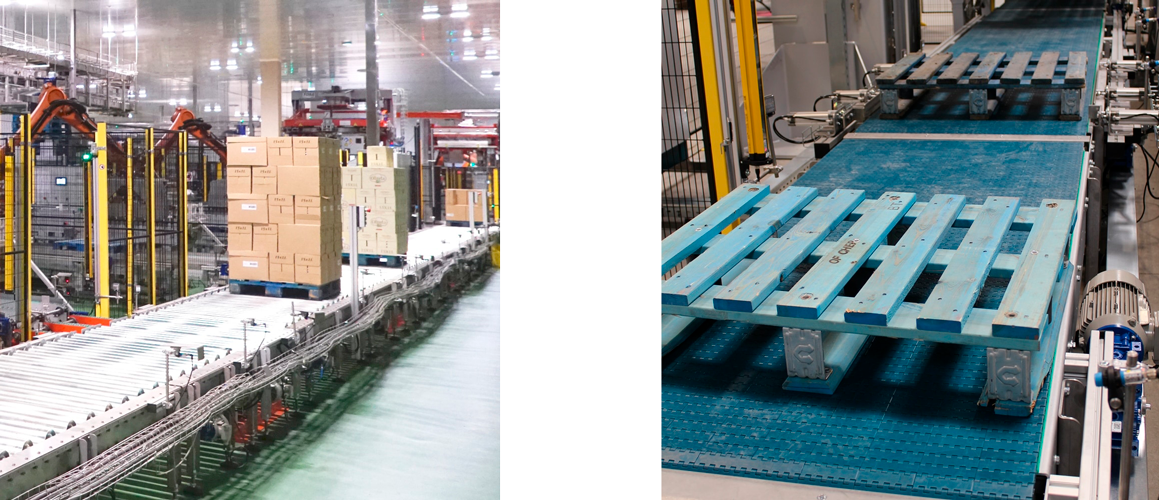

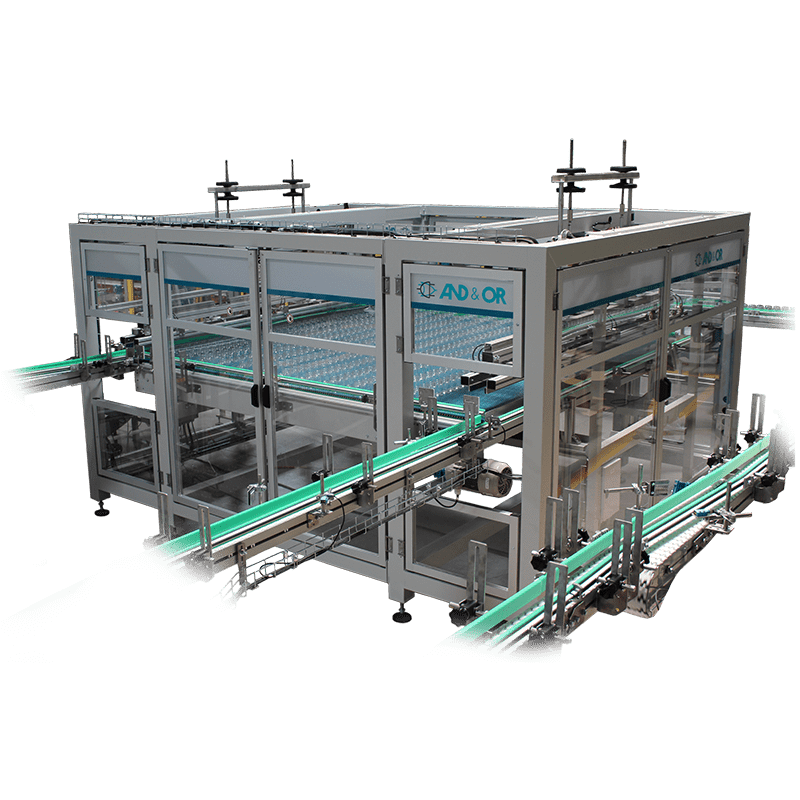

Accumulation tables:

AND&OR’s accumulation systems guarantee the uninterrupted running of the bottle line in reduced space in order to maximize production efficiency. We have different systems suitable to process both empty and filled PET/HDPE bottles.

Accumulation table for empty bottles

Accumulation table for filled bottles

Accumulation table advantages

- Compactness: saves space in comparison to traditional accumulation systems.

- Better surface/accumulation time relationship

- Simple maintenance and preservation

- No risk of bottleneck formation

- Possibility to empty pre-forms ‘oven on accumulation table in case of line stoppage.