Tray and box packing

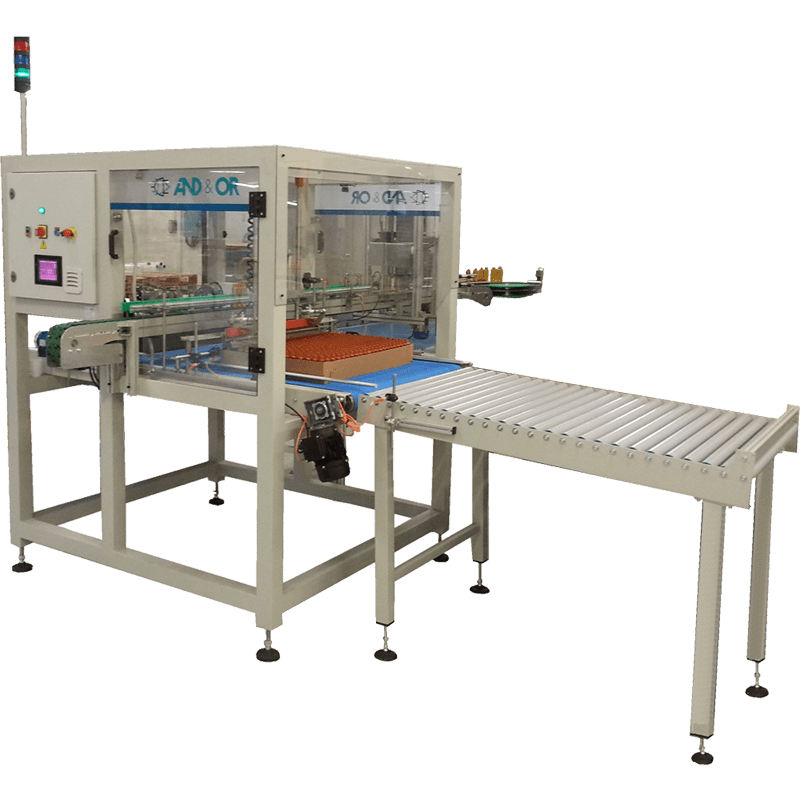

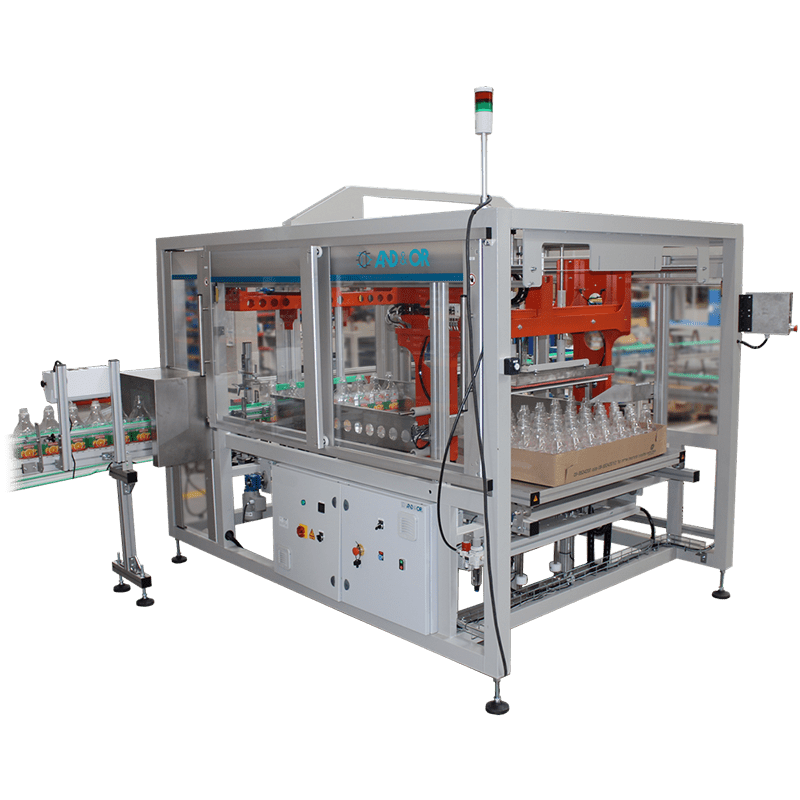

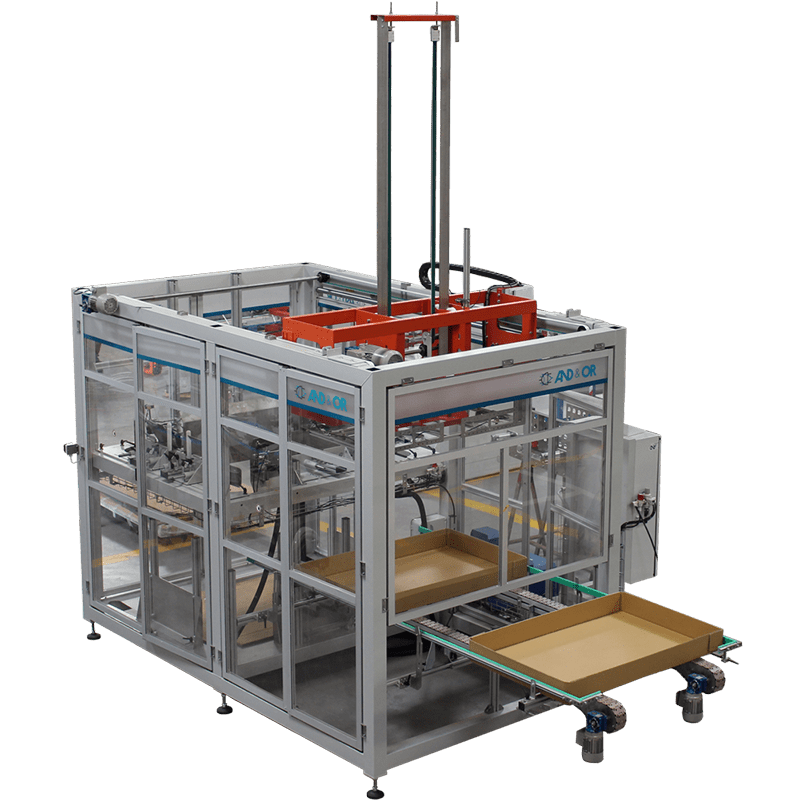

Automatic box packers for cardboard boxes (B1), Pick&Place system

Our EPA system performs the bottles box packing, for both empty and filled containers.

The picking headstock is designed according to bottle formats, being able to pack bottles with no neck ring, either heavy bottles or empty light ones.

Characteristics

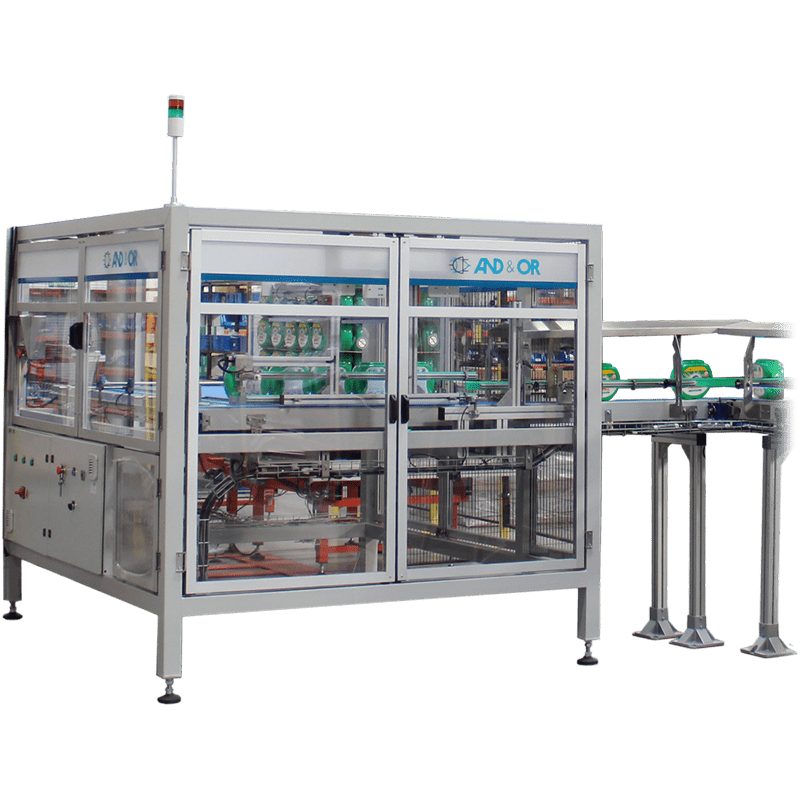

Tray packers for empty bottles

These machines have several optional elements depending on each customer needs: automatic opening of folded trays, support to work with a double tray, up to ten trays storage for higher autonomy, etc.

These machines have been designed to cope with different bottle shapes and line requirements: trays type, available space and automation needed. Tray sizes are configurable.

Installed in an area adjacent to the blowing, the tray packers allow the operator to attend to several machines simultaneously.

| SERIES | Tray type | Operation |

| ETS | Preformed upside trays | Three positions packer:

Output area, filled tray |

| ET | Preformed upside trays | Three positions packer:

Output area, filled tray |

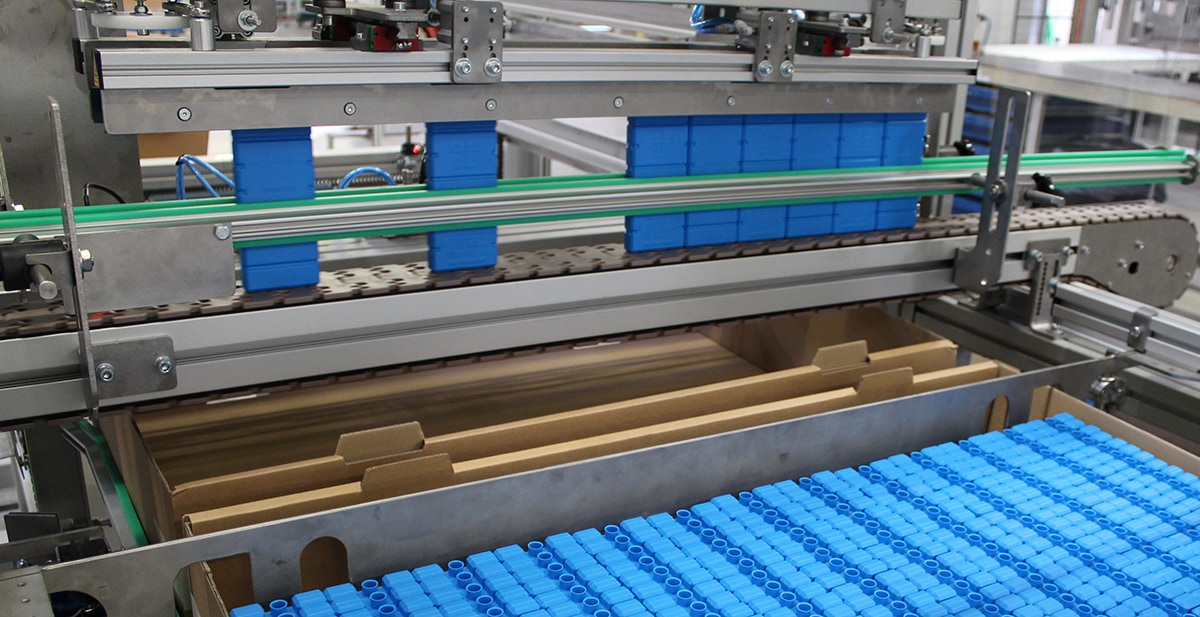

| ECA | Folded trays or with one side opened | Layer formation in buffer space Insertion of whole layer into the tray, holding the layer of bottles by its four sides.Optionally, bagging system can be integrated. |

Automatic tray former to fold and glue cardboard sheets to form trays (hot melt system) or forming trays by fitting the cardboard.

It is appropriate to be installed next to the (filled or empty) bottle palletizer or in isle mode with a tray stack at the machine output.

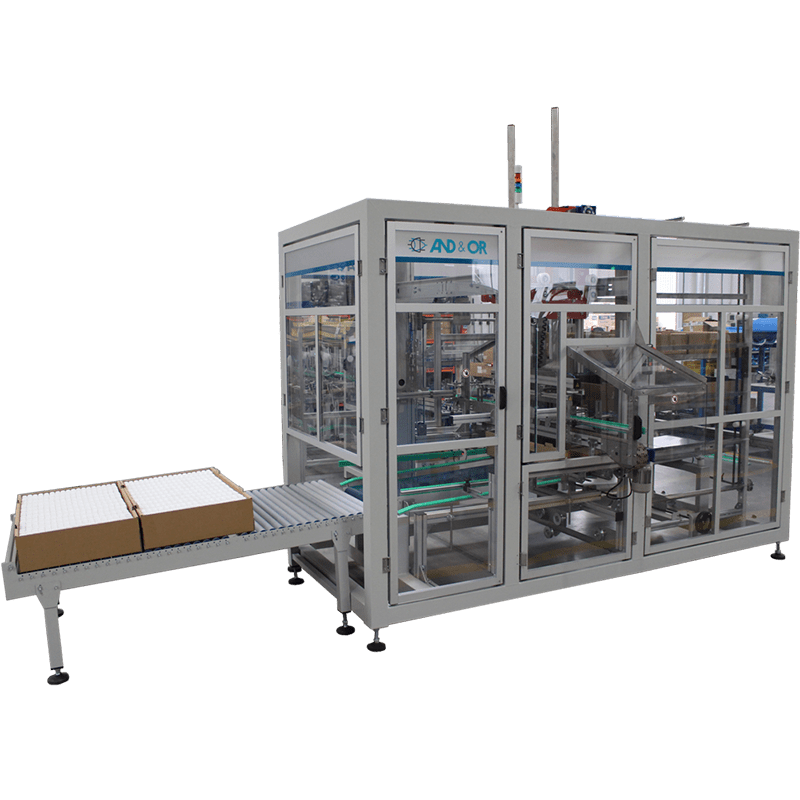

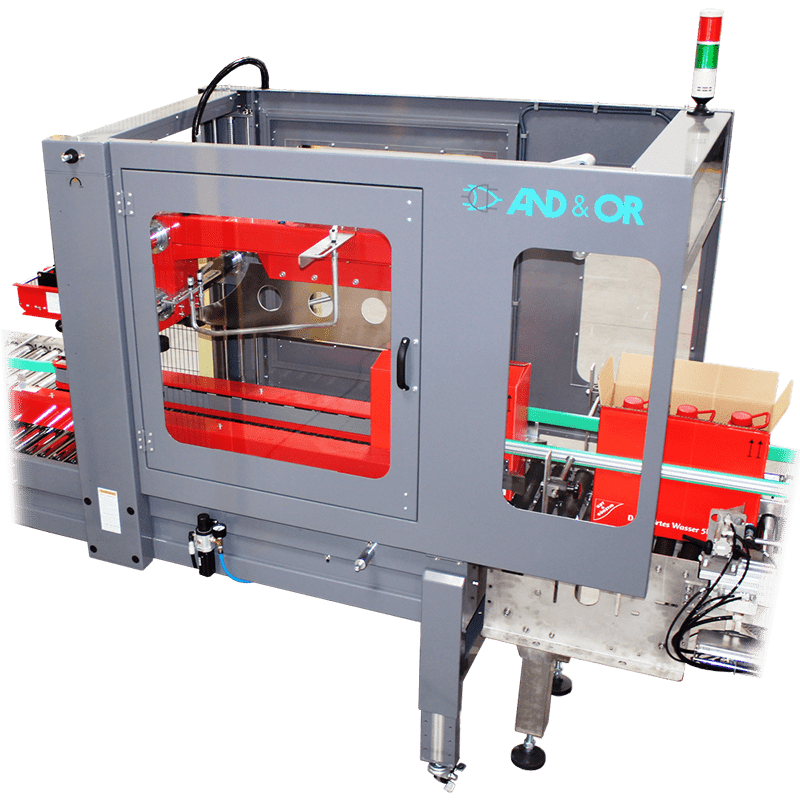

Automatic box forming and cardboard sealing to make boxes, by adhesive tape or hot glue.

Optionally, an automatic or manual box closing equipment can be added, using adhesive tape or hot glue.

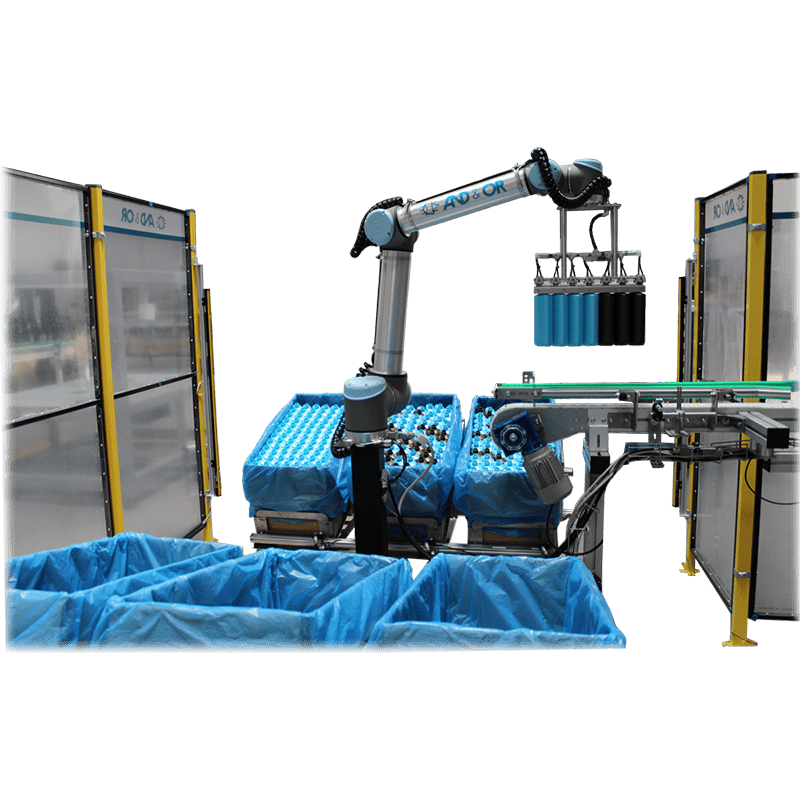

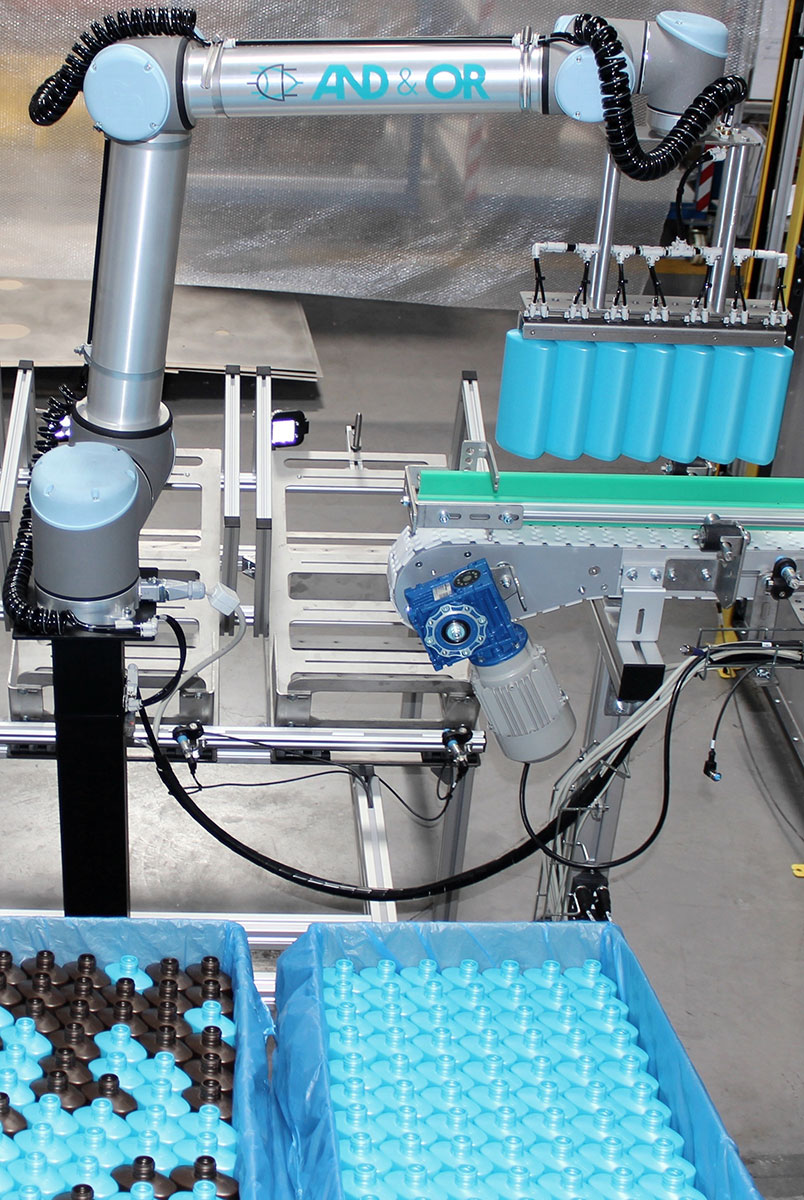

Collaborative solutions

Collaborative robots – RC Series

The collaborative robots are used in low cadence lines and low weight product handling (up to 15 kg). Being collaborative and without need of external protection, they take up a very tight space in the factory.

.

|

Why choosing our system?

Why choosing And&Or?

PACKING MACHINES

Tray packing for empty bottles

ECAThis system completes a bottle layer over a metallic base. The layer is slide from the table to the tray by a four side frame to avoid the falling of unsteady bottles.

Optionally:

- It can include an integrated bagging system in the same machine, Model ECA-BT.

Layer configuration desk

EMAM/EMAEMAM: Layer configuration desk on motorized belt.

EMA: Layer configuration desk on metallic base.

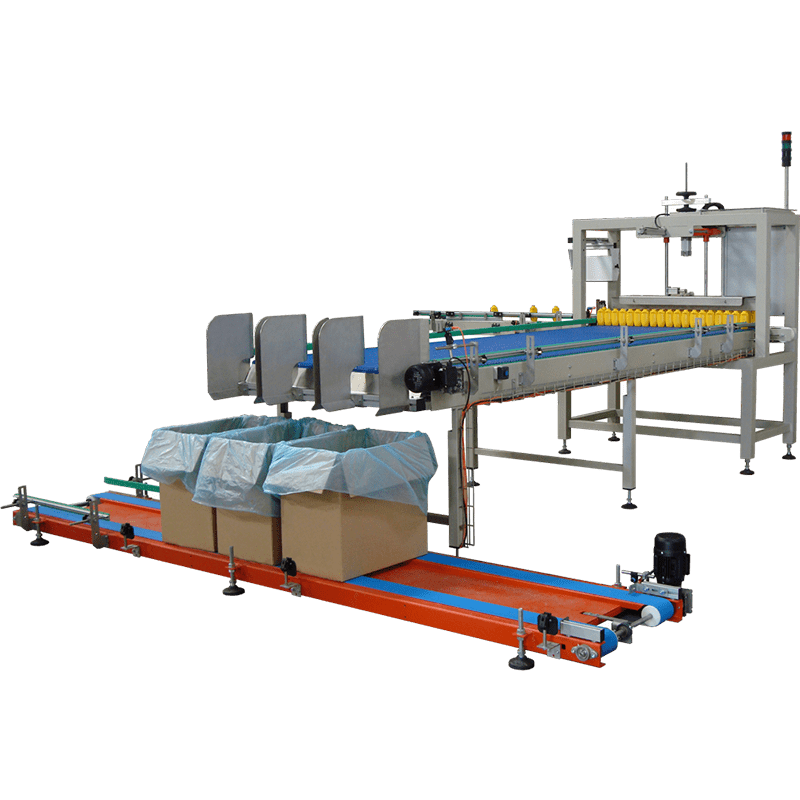

Cooling desk and bulk box packing

MA40Cooling desk before bulk storage of bottles into boxes.

Bottle counting system and box dosing management.

Automatic tray former

PFCAutomatic tray former: this system folds and glues cardboard sheets to form trays (hot melt system). It is appropriate to be installed next to the (filled or empty) bottle palletizer or in isle mode with a tray stack at the output of the machine.

This model allows both upside and inverted trays. The supply of the cardboard sheets is made manually, stacking them in an annexed warehouse.

The machine can be adapted to different sizes/designs of trays.

Maximum production rate: 60-120 trays per hour (depending on model).

To higher production rates, check model PFCH.

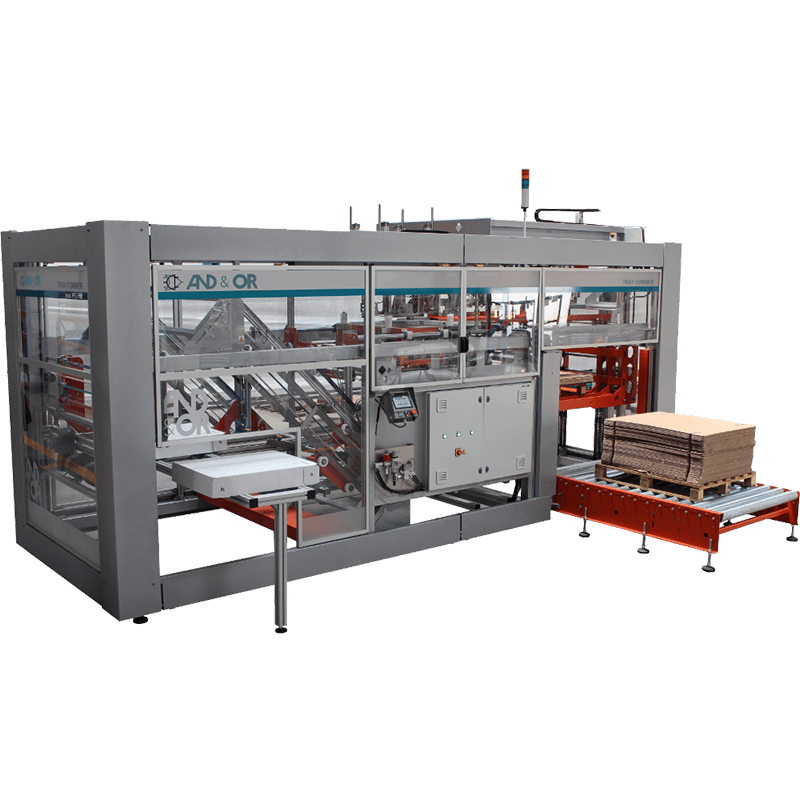

Automatic tray former with turning system, high speed

PFCHThis automatic tray former folds and glues cardboard sheets to form trays (hot melt system). It is appropriate to be installed next to the (filled or empty) bottle palletizer or in isle mode with a tray stack at the output of the machine.

This tray former folds upside trays (for inverted trays it is necessary to add a turning system at the output of the machine). The sheets are supplied from a pallet placed on the input pallet conveyor (optionally, an empty pallets stack can be added at the output).

The machine can be adapted to different sizes/designs of trays.

Maximum production rate: 300-500 trays per hour (depending on model).

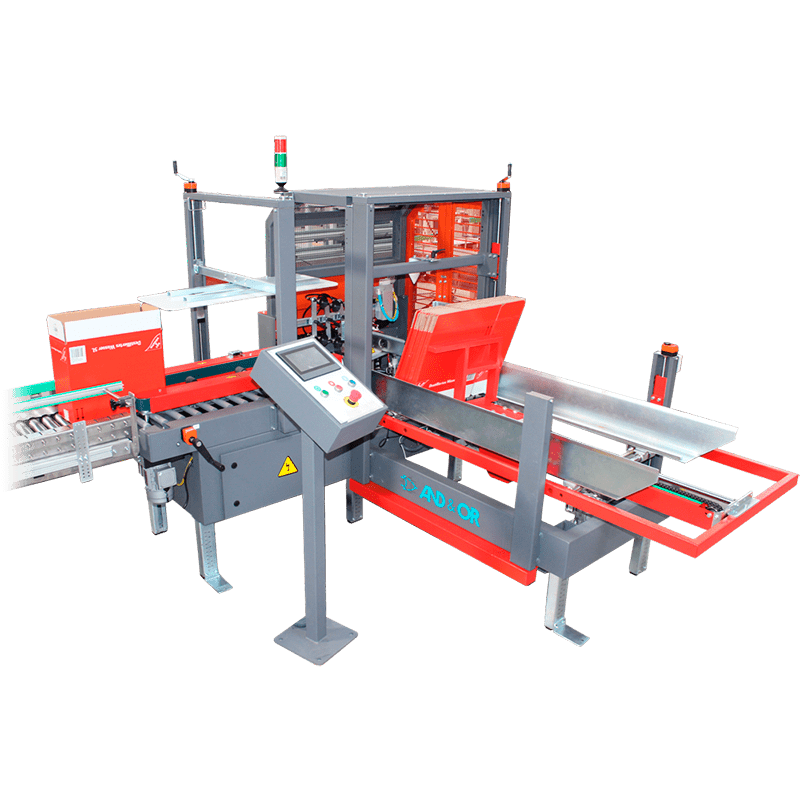

Automatic box former

Automatic box forming and cardboard sealing to make boxes, by adhesive tape or hot glue.

Box closing equipment

Automatic or manual box closing equipment, using adhesive tape or hot glue.

Downloadable content

The content is restricted, in order to have access it is necessary to register