Finishing systems for bottles

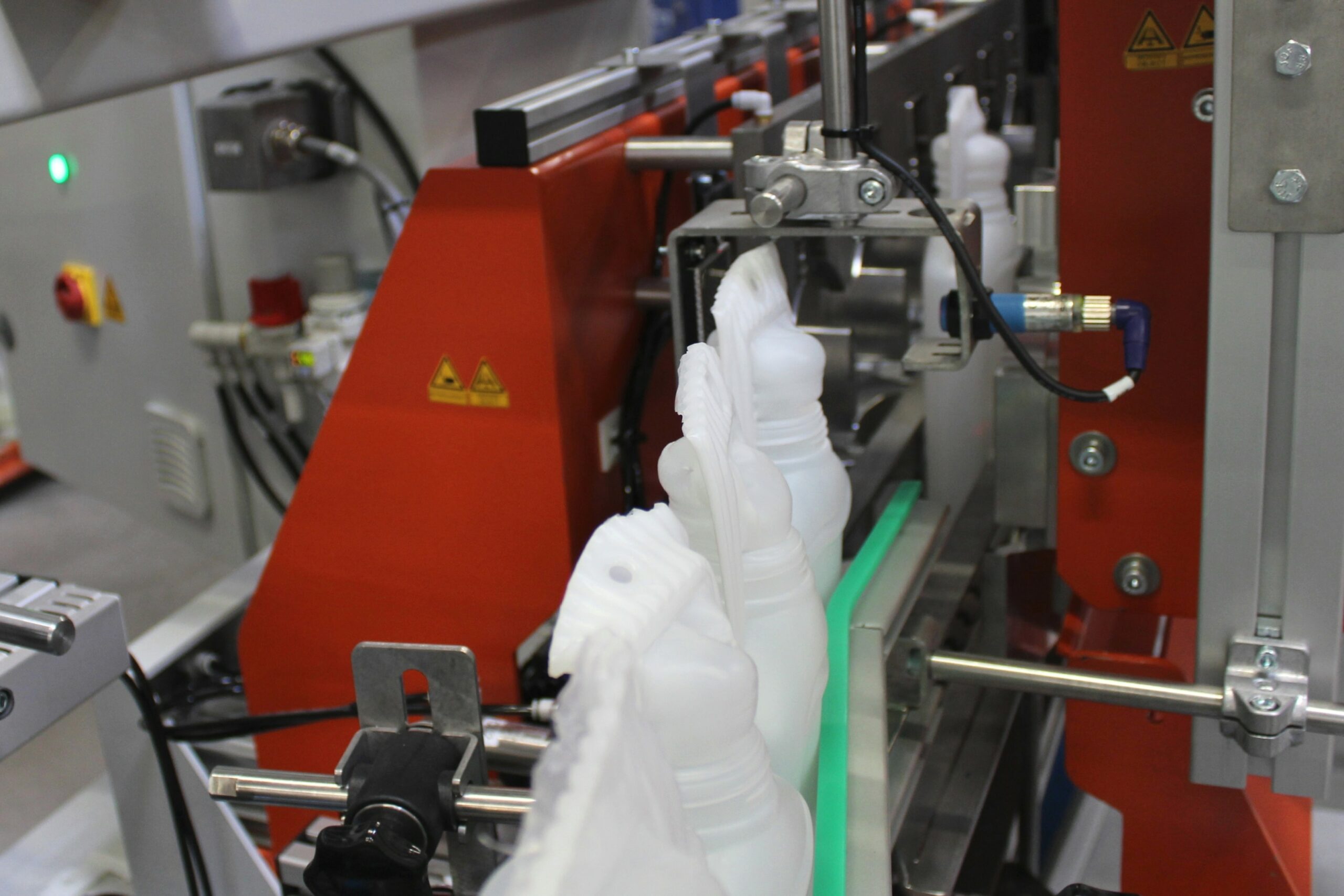

Trimmers

Both linear and rotary trimmers, with different models that adapt to line speed, bottles’ shape and material. Optionally a leak tester can be integrated in the same equipment.

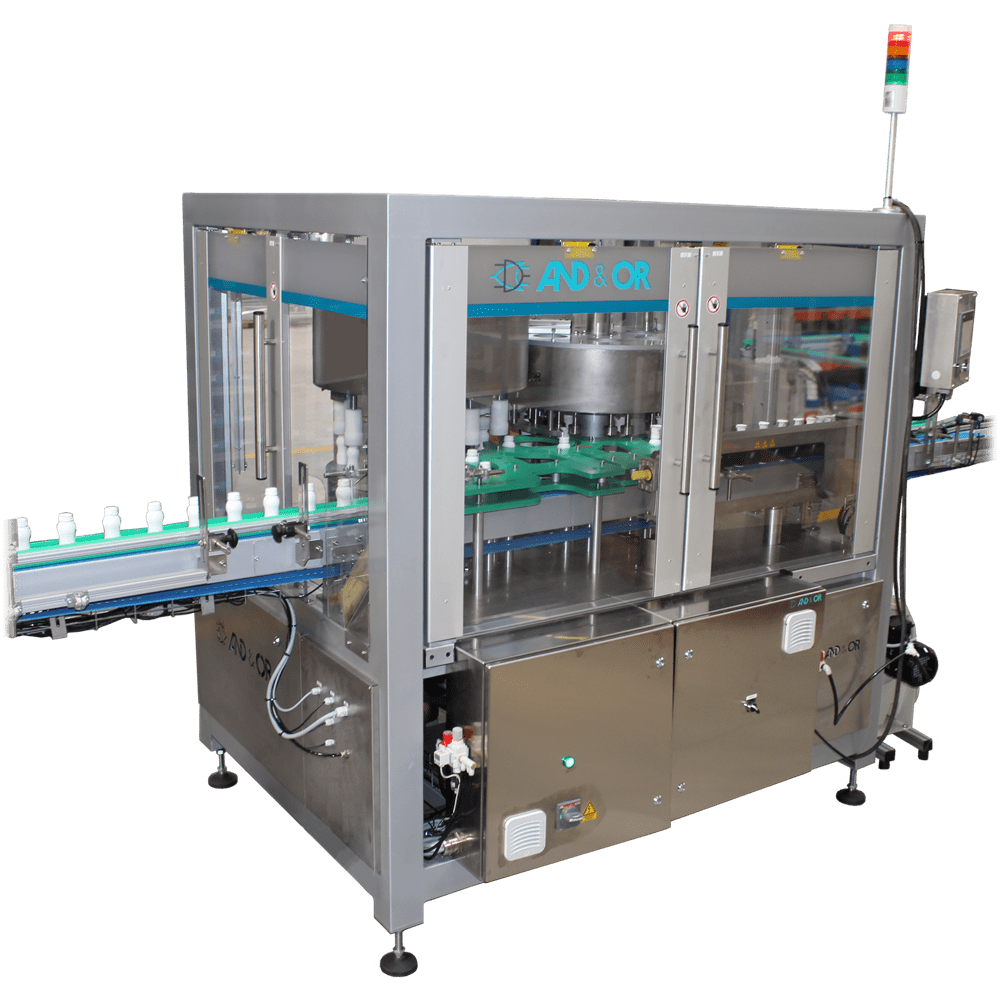

Milling systems

It performs the milling (eliminating the polyamide) on HDPE bottles neck surface. It achieves a perfect finishing thanks to its servo driven, smooth milling system, reaching a high precision.

Automatic deflashing systemss

Bottles deflashing machine including pneumatic system for cavities opening and closing, and a mold/contramold set for bottles deflashing.

Coating system

AND&OR Coating system is able to lubricate PET bottles spraying an anti-static coating. This avoids possible problems on the filling and packaging lines, like bottle jamming and scuffing.

It includes a lateral conveyor that holds the bottles by the neck while they’re being sprayed and puts them back to a belt conveyor.

Why choosing our system?

Why choosing And&Or?

BOTTLES FINISHING MACHINES

Integrated rotary trimmer and leak tester

CC-LS

Integrated milling machine and leak tester

FH-LSIntegrated milling machine and leak tester for plastic bottles.

It is usually installed after the extrusion blow molding equipment. It achieves a perfect finish at high precision thanks to the servo-motorized milling unit.

This equipment includes a particles extractor and avoids the contamination inside the bottle during the milling process.

Its fully automatic system simplifies its use and maintenance, without requiring any special action for the operation.

Maximum production rate: depending on model.

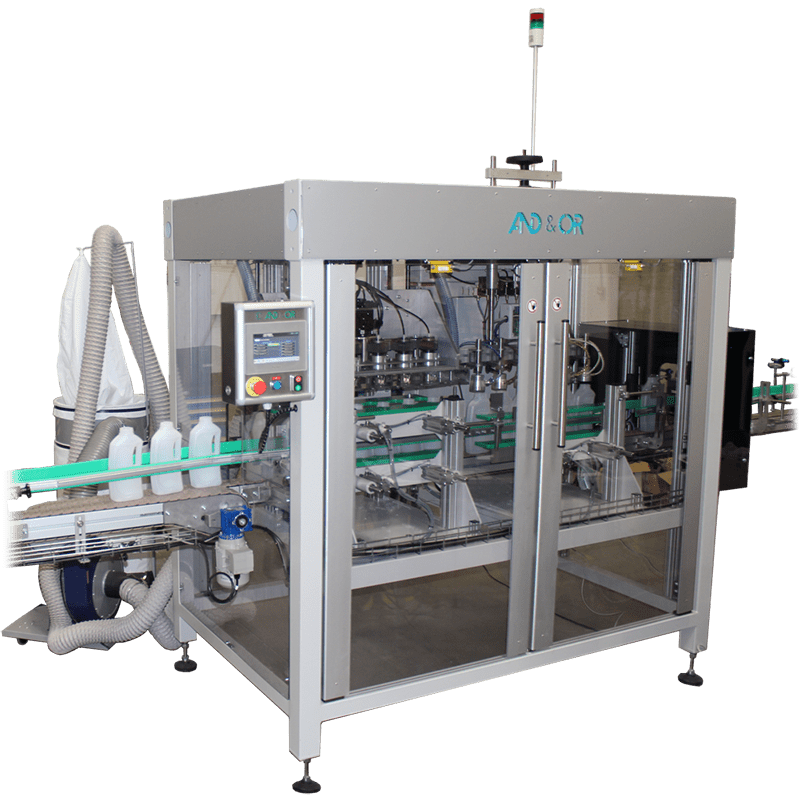

Integrated milling machine, leak and weight tester

LW-FHIntegrated milling machine, leak and weight tester for plastic bottles.

It is usually installed after the extrusion blow molding equipment. It achieves a perfect finish at high precision thanks to the servo-motorized milling unit.

This equipment includes a particles extractor and avoids the contamination inside the bottle during the milling process.

Its fully automatic system simplifies its use and maintenance, without requiring any special action for the operation.

Maximum production rate: depending on model.

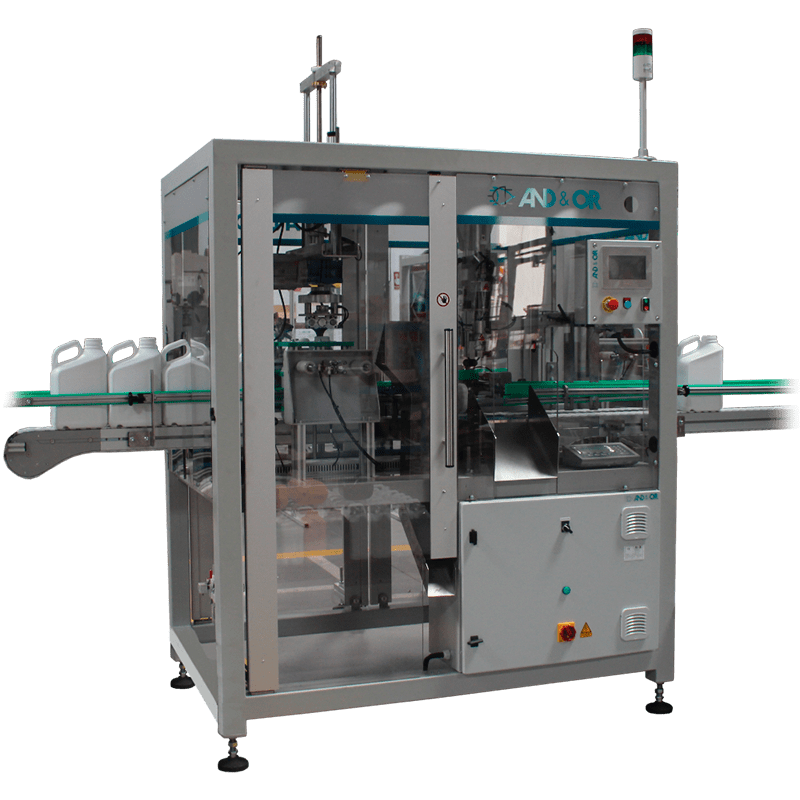

Deflashing system

REBottles deflashing machine including pneumatic system for cavities opening and closing, and a mold/contramold set for bottles deflashing.

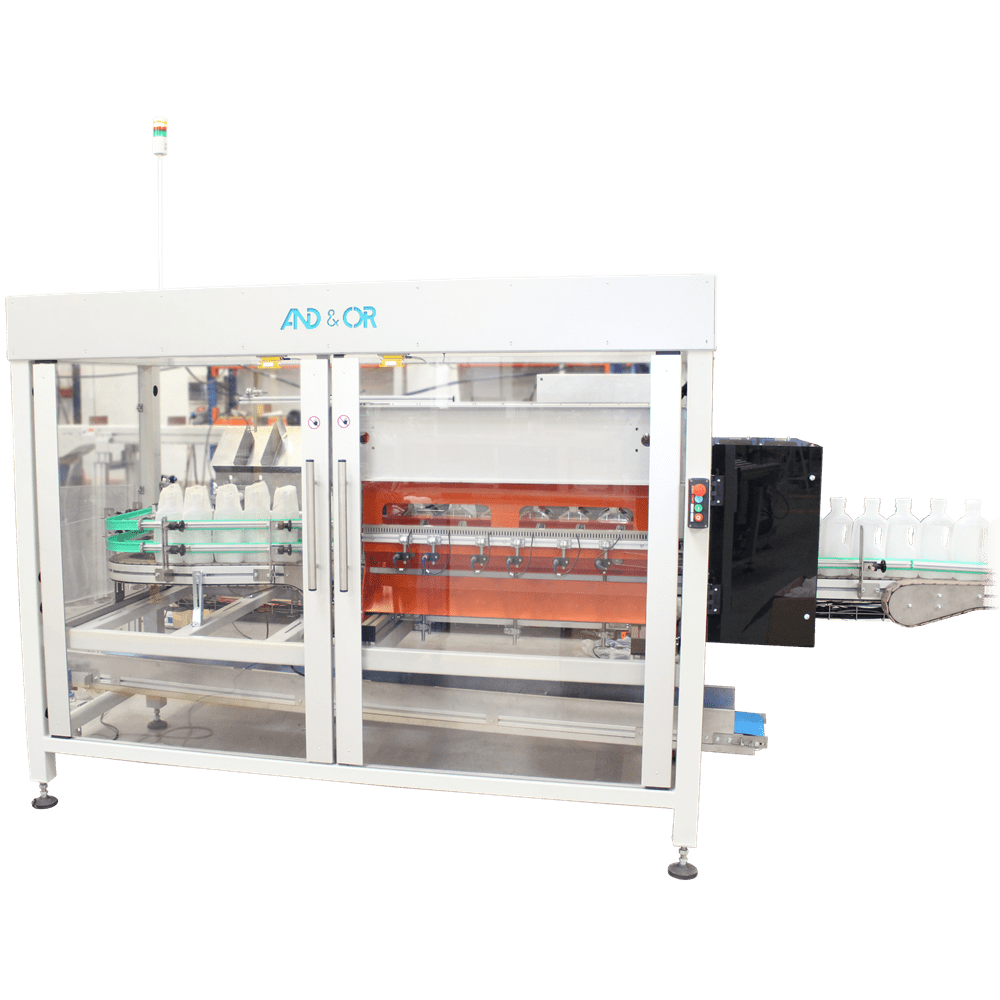

Coating system

CSAND&OR Coating system is able to lubricate PET bottles spraying an anti-static coating. This avoids possible problems on the filling and packaging lines, like bottle jamming and scuffing.

It includes a lateral conveyor that holds the bottles by the neck while they’re being sprayed and puts them back to a belt conveyor.